Bright lights from TV cameras glinted off the 108-foot long wing spar as an automated drilling machine performed its programmed maneuvers.

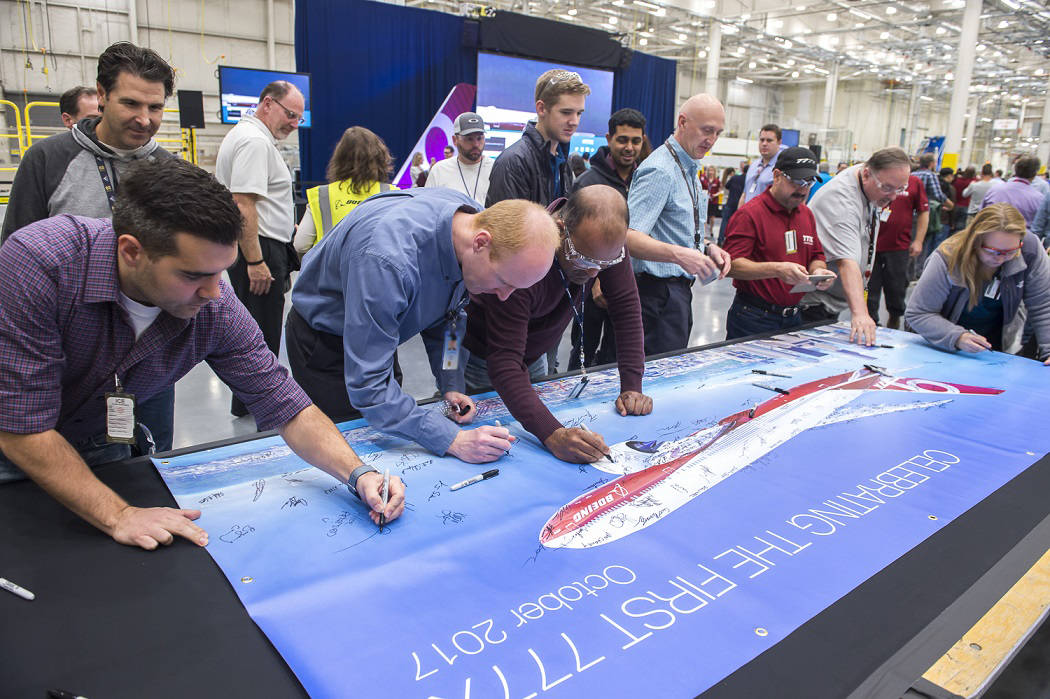

About 500 employees, members of the media and customer representatives joined an online audience to witness production of the first wing spar for the first 777X that will take to the skies.

The event marked a major production milestone for the program — the first hole drilled in the first wing spar that will be part of a flying airplane.

Employees expressed their enthusiasm about the beginning of production.

“It’s been so exciting to see the first parts come through after years of preparing for the first airplane,” said Paul Clark, 777X wing assembly mechanic. “We’ve got a great team here and all of us are eager to begin using the new equipment and processes.”

Fabricated in the Composite Wing Center in Everett, Wash., the front and rear spars had their first voyage to the new 777X wing assembly building.

“The 777X wing is a composite, so it is much lighter and maintains good strength characteristics,” said Mary Manning, 777X design engineer. “This allows the airplane to be lighter, which results in greater performance and fuel efficiency. This will be better for our airline customers.”

In anticipation of the 777X, the production building has been completely refurbished, with new tooling for the wing spars installed, tested and qualified.

Airplane test and certification is scheduled to occur in 2019 with first delivery in 2020.